×

×

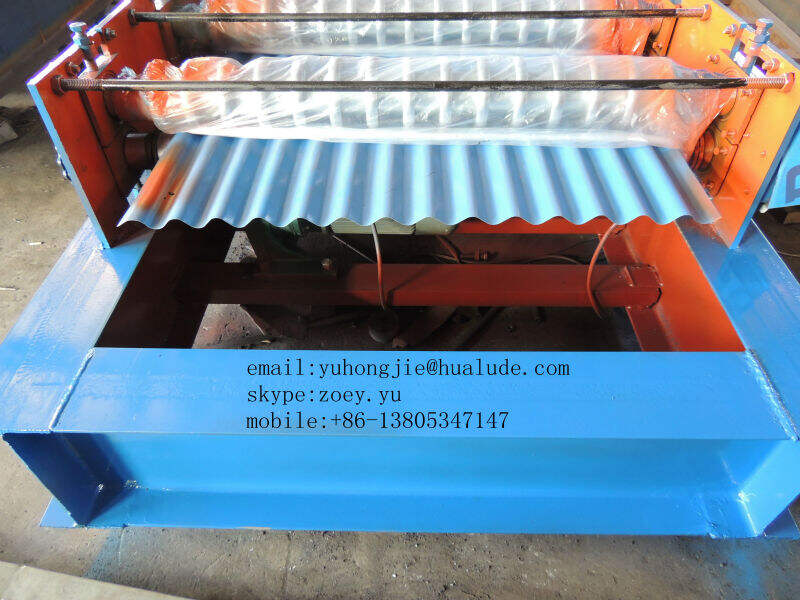

(1) Suitable material: color steel

(2) Thickness of the plate : 0.3-0.8mm

(3) Input width of the plate: 1250/1000mm

(4)Width of the plate after forming: 1000/800mm

(5) Productivity :1-3m/min

(6) Roller steps :16rows

(7) Roller material: 45# steel Rolling chromium thickness:0.05 mm

(8) Diameter of active shaft: 80mm

(9) Wall thickness of the main forming machine:16mm steel plate

(10)Main forming machine body : 300mmH steel

(11) Transmission chain is1’’

Reducer is 5.5kw which works stably and no noise

(12) Cutting hydraulic systerm adpats CDF-10 gear pump,the motor power is 4kw, no noise, work stably, long life expentancy.

(13) PLC control systerm, easy to operate, high precision and work stably.

(14) Dimensions of major structure:8500mm*1600mm*1200mm

| metal siding roofing panel roll forming machine |

Model |

Shibo-1040/1035 |

Forming size |

8000mm*1600mm*1600mm |

|

Weight |

4.5 T |

|

Host big frame structure |

Frame welded |

|

Roll station |

top:13row lower:15row |

|

Axial material |

45# steel |

|

Out diameter of shaft |

Φ75 |

|

Roller materials |

45# steel hard chromium plating |

|

Drive |

By chain |

|

Sprocket chain |

25.4mm |

|

Main power |

4kw |

|

Working speed |

8-10 m/min |

|

Material thickness |

0.3-0.8mm |

|

Made board |

16mm |

|

Feeding width |

1200mm |

hualude

We've been exporting field in China for 18 years, we have our personal factory of roll forming machine, galvanized roofing sheets and iron nails, we are quite expert in exporting and trust in me personally, we are going to give you the top goods and service better.

In search of a dependable and machine produce efficient sheet steel roofing for the construction project? Take a look at hualude top of the line steel roofing roll machine developing.

Hualude's Corrugated Sheet Metal Roofing Roll Forming Machine developing a good and device durable that will help you produce top-quality, precision-cut roofing panels with simplicity. Featuring a construction sturdy technology advanced this roll forming device is good for both little- and large-scale roofing manufacturing applications.

Fashioned with this product quality materials being greatest, Hualude's Corrugated Sheet Metal Roofing Roll Forming Machine forming designed for a myriad of metal materials including aluminum, metal, and copper. Its high-level design and control intelligent permit simple operation and rapid manufacturing of personalized roofing panels in many different sizes and shapes.

Featuring its high production efficiency, zero-maintenance requirements, and durability lasting Hualude's steel roofing roll forming device is the perfect investment for about any specialist or building owner who has to make top-quality, durable roofing quickly and reliably.

You receive the work finished with rate, precision, and ease whether you are looking after a construction new, replacing an old roof, or merely require more roofing material when it comes to warehouse or commercial area, Hualude's corrugated sheet steel roofing roll forming device might help.

So why wait? Purchase Hualude's Corrugated Sheet Metal Roofing Roll Forming Machine today and simply take your roofing manufacturing to your degree next. We stay behind our services and products and are specialized in supplying the best in quality to our customers, performance, and dependability. Order your machine and start experiencing the Hualude difference today huge.