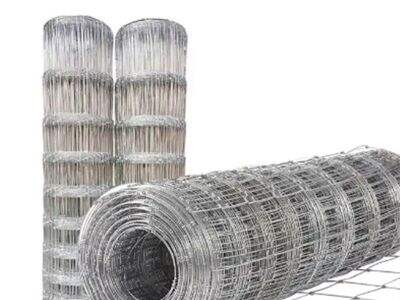

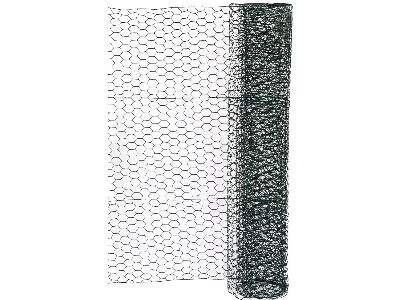

Galvanized metal mesh is strong and durable, but how do you know it will last? When you purchase from hualude, you want to know that the mesh won’t break or rust easily. Testing its toughness means seeing if it can withstand hard use without damage. There are various approaches to this, ranging from basic visual surveys to more hands-on examinations. Some require special tools; others merely require watching and handling them carefully. It helps to know which tests to choose so you can avoid trouble later. So now let’s look at how to test galvanized metal mesh that way you know what it is

How to test the durability of galvanized metall meshes as wholesale

Since many wholesale buyers will be purchasing in large quantities, testing for durability is crucial. First, always check the coating. The zinc coating will also cover the wire mesh uniformly, ensuring that the metal doesn't rust. If you notice spots where the coating is thin or absent, that mesh may rust earlier. A fairly easy one is to examine your scalp in good light, and possibly with the aid of a magnifying glass. Next, experiment bending some mesh pieces by hand. Firm galvanized mesh gives a little but does not bend, crack or break very easily. If you hear cracking sounds while applying force to the metal pieces, or if you can see a piece of metal snap off entirely, that’s an indication that the mesh is weak. Another one is salt spray test to simulate the influence of salty air on the metal. You can achieve this by spraying the mesh with a saltwater solution and letting it dry for a few days. Decent galvanized mesh will stand up to rust for long after that. Also, look for any sharp edges or exposed wires. These are indications that the mesh may not be durable or safe to handle. Not just the paper or pictures. Touch and test yourself. It depends on how thick the wire is too

How to Determine the Strength and Longevity of your Galvanized Metal Mesh

There are many reasons why galvanized metal mesh is so strong and durable. The tensile strength test is one of the most effective methods. This test stretches the mesh until it fails. The more force is required to break, the stronger is the mesh. Special machines can do this, but if you don’t have one, pull off a smaller piece by hand so you can feel its strength. Another is the scraping test. This involved abrading its mesh material with rough grinders to observe if the zinc coat wears out in a short span of time. If the coating rubs off after only slight rubbing, you can bet that the mesh won’t last long in tough conditions. At hualude, we employ machines that replicate this rubbing so we can find out how tough our mesh really is. Also, consider corrosion resistance tests. One early simple test is the salt spray. But there’s also the humidity test, in which mesh is placed in a humid room for days at a time. What’s good galvanized mesh will still look good, and won’t rust. Another important factor is flexibility. If mesh is too rigid, when you bend it or shape it, it may crack. It may not retain its shape if it is too soft. The optimal mesh, he says, strikes a nice balance. You can test that by simply bending and twisting the mesh repeatedly. If it remains intact, that’s an indication of being in good shape. There’s a simple, easy but important visual test. Inspect for any cracks, holes or spots of rust. Also, examine the mesh aperture and wire diameter. One that has mesh and the size and thickness of a hinge pin are uniform generally wears better as the load is spread more effectively. At hualude, we combine experience with skillful testing to ensure that our galvanized metal mesh offers optimal strength and durability

Where You Can Get Quality Durability Testing for Bulk Galvanized Metal Mesh

When you’re making a significant purchase of galvanized metal mesh material strong enough to last, it’s important. This is why you’ve got to find such amazing durability testing services. These services test the metal mesh to determine if it can stand up to challenging conditions without breaking apart or rapidly wearing down. If you ever need to purchase large volume of galvanized metal mesh, you should try to find out metal product testing companies. These companies utilize special machines and tests to test the strength of the mesh, its resistance to rust and how well it performs under various weather or pressure. To combat instances of ‘fake’ merchandise, from hualude for instance we have reliable testing facilities in place which makes purchasers feel secure in the quality of their purchases. We understand that metal mesh needs to be strong and work in environments like construction sites, fences and other areas where a durable reinforcement perspex is needed! These reports will allow you to see how strong the mesh is and whether or not it fits your needs. The choice of a good testing service saves you money because you do not have to buy weak or low-quality mesh. Keep in mind, purchasing a significant amount of galvanized metal mesh is an investment, and testing will make sure you get the best product for your money. Here at hualude we ensure the testing is conducted properly and we always provide the results to our customers. This way you can be sure your bulk galvanized wire mesh purchase will last awhile, and be ready for the job you have in mind

Points Wholesale Buyers Should Understand

If you’re purchasing large quantities of galvanized metal mesh, it’s essential to understand the following so that you can get a good deal. First, let’s learn what galvanized metal mesh is. It is a metal wire coated with a protective layer of zinc so it does not rust. This helps the mesh last longer, particularly when it’s used outdoors or in damp environments. But not all galvanized metal mesh is equal. A thicker zinc coating might also affect how long the mesh will remain strong and attractive. Here at hualude, we ensure our mesh contains the correct amount of zinc protect it well. That size and shape of the holes in its mesh is also a big factor. Smaller holes or larger ones, depending on what you want the mesh for. Tiny things can be eliminated with smaller holes, and some air or water can pass through larger ones. You’ll also want to look at the wire’s thickness, which contributes to how strong the mesh is. A thicker wire generally makes for a stronger mesh. When you are ordering a wholesale, ask for samples first. This allows you to see and feel the mesh before making a larger purchase. We offer samples at hualude to support buyers. Also consider where and how the mesh will be used. Certain projects will require mesh that can support a lot of weight or withstand strong winds, while others may require rust-proofed mesh after many years. Understanding this helps you to select the correct variety of galvanized metal mesh

How to Impact and Wear Testing for Commercial Galvanised Metal Mesh

It's crucial to test galvanized metal mesh for impact and wear, especially if people will be using it in places that might see a lot of hits or rubbing. Impact tests measure how well the mesh can withstand abrupt, strong forces, such as something crashing against it. Wear tests reveal how the mesh holds up to rubbing or scraping over time. At hualude, we have a solid system in place to perform these tests and ensure our metal mesh is standing up to the challenge. In oder to do impact testing, we start with a small segment of the galvanized metal mesh sample. Then, we employ a device that either releases a weight or hits the mesh with a standard force. We pay close attention to whether the mesh bends, breaks or becomes damaged. If the mesh remains unbroken and isn’t weakened by cracks, it is considered a success. Which is to say that it can take real-life bumps and knocks like debris hitting the land, tools bumped up against it. At hualude, we check our galvanised wire mesh undergoes impact and wear test before packing. This enables our customers to have confidence in the mesh durability in commercial applications such as building safety barriers, industrial screens or fencing outdoors. It's also essential to have controlled environmental conditions (such as, testing temperature and humidity are adjusted at certain levels). This makes the test fair and assures that the results are reliable. What’s more, complete test results recording can help us to enhance our products and solve any potential problems rapidly. Through these tests, hualude ensures the galvanized metal mesh strong, safe and ready to get to work. If you need no nonsense metal mesh that will hold up to any abuse find a company testing it in these scenarios. That way you receive the highest quality mesh to protect your investment and ensure that it keeps stuffing safe

Table of Contents

- How to test the durability of galvanized metall meshes as wholesale

- How to Determine the Strength and Longevity of your Galvanized Metal Mesh

- Where You Can Get Quality Durability Testing for Bulk Galvanized Metal Mesh

- Points Wholesale Buyers Should Understand

- How to Impact and Wear Testing for Commercial Galvanised Metal Mesh

/components/head/pics/ico-email.png)

/components/head/pics/down.png)

/images/share.png)

/components/foot/pics/gotop-email.png)

/components/foot/pics/gotop.png)