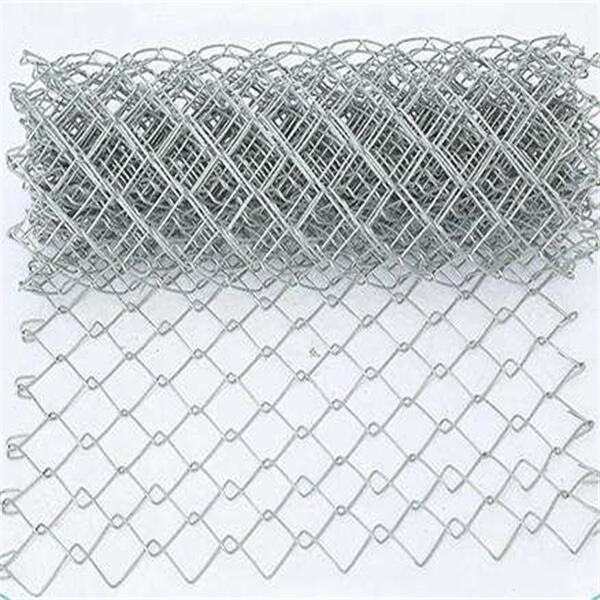

Because of this steel wire galvanization is a critical process to prevent steel wire rust. Rust can weaken metal, so prevention right through it is crucial. This process allows the wire to have a longer life and remains stiff. The wire is then dipped into a hot, molten bath of zinc to galvanize it. The zinc ends up coating the steel wire in a specific layer. This process is referred to as hot-dip galvanization. It works remarkably well, as the zinc coating prevents rust and protects the steel wire from being damaged.

One of the most widely used materials in various industries, and particularly in the construction and building industry, is galvanized steel wire. It is also very strong, durable, and rust-preventive, which explains its popularity. It is typically employed by people who use this type of wire to construct things like buildings and bridges and other sturdy items. Galvanized steel wire is not afraid of poor weather, so it is ideal for use outdoors. It is resistant to rain, snow, or high winds without damage. It's also used in manufacturing machines and vehicle components that must be tough and longlasting. This is the reason why a lot of people use galvanized steel wire in their projects.

This creates a galvanized coating that makes the wire much stronger. protected the wire from rust and other forms of damage through a special zinc layer on the outside. Steel wire rusts readily in the rain and humidity and is best kept dry. This rusting can cause the wire to become weak and less useful. But galvanized steel wire is a different material. Its protective zinc layer makes it more resistant to rain and sun. That means this wire will last far longer, even under the elements.

Many jobs can benefit most from selecting galvanized steel wire— this option is both smart and cost efficient. This is one of the best ways to prevent the rust without spending too much money. This wire is a low enough price that makes it ideal for businesses and builders. Another reason many people use it is that it is easy to take care of. It saves money on the long term, because it does not need to be replaced that often, since it can last for a long time. Especially when the materials will face harsh weather, companies like to use strong and durable materials.

Here are some key points to consider when it comes to selecting galvanized steel wire. The thickness of the zinc coating is crucial. The thicker the coating, the more resistant to rust and damage it will be. Also, take into account the size of the wire, measured in the gauge. A general rule: the thicker the wire, the stronger and sturdier it will be. Using an appropriate gauge will greatly affect the performance of the wire for various ends. Finally, To choose a reliable supplier, such as Hualude. It really helps you become organized and keep your projects safe and slow working.

Dezhou Hualud Hardware Products Co., Ltd., first established in 1996, was reestablished in steel wire galvanized under its current name. Is both an exporter of hardware and a manufacturer. We have been exporting to numerous countries since the beginning of our existence. Our name is well-known among our customers.

Our steel wire galvanized to quality doesn't stop with sales. We offer a complete after-sales service to ensure the efficient installation and operation your hardware devices. Our team of experts is dedicated to solving any problems quickly and quickly. We believe we can provide a reliable and sustainable solution for your hardware needs.

Our company, which is based in South Korea, Japan, and other countries, is introducing the steel wire galvanized top multi-station machining centers, CNC lathes and CNC milling equipment, as well as more than 1,000 units of modern technology, high-precision equipment. This will ensure that our products conform to our strict standards of quality.

We value the customer's experience and strives to provide top-quality service prior to steel wire galvanized. Our expert team is available to answer your questions, help and work with you to come up with the perfect solution to meet your needs. We are committed to providing the smoothest and most stress-free shopping experience, so you can count on us to meet all your needs when it comes to purchasing.

/components/foot/pics/gotop-email.png)

/components/foot/pics/gotop.png)